- Home

- >

- Knowledge Center

- >

- Blogs

Blogs

Sharing knowledge is key to an innovative and healthy industry! This knowledge center is therefore a central place on our website to share information. Read all about our industry in the blogs below!

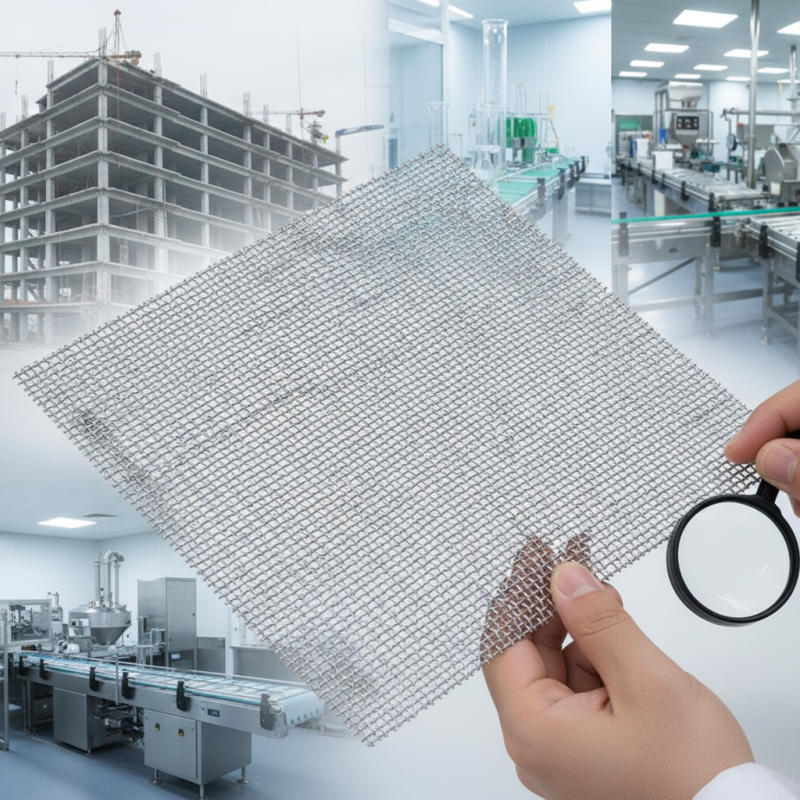

2026 Top Uses of Stainless Steel Woven Wire Mesh?

In recent years, the demand for stainless steel woven wire mesh has surged across various industries. According to a report by Global Market Insights, the stainless steel mesh market is expected to reach $1.2 billion by 2026. This growth is driven by its application in construction, pharmaceuticals, and food processing sectors.

Industry expert Dr. Emily Carter emphasizes the importance of durability and resistance in this material. She states, "stainless steel woven wire mesh combines strength and versatility, making it ideal for diverse applications." The usage of stainless steel woven wire mesh not only enhances product quality but also ensures longevity.

However, challenges remain in sourcing high-quality mesh and ensuring uniformity in production. Companies are urged to reflect on their supply chains and material choices. As the industry evolves, understanding the top uses of stainless steel woven wire mesh will be crucial for innovation and sustainability.

Applications of Stainless Steel Woven Wire Mesh in Industry

Stainless steel woven wire mesh has become essential in various industries. Its unique properties make it highly versatile. In construction, it provides both structural support and aesthetic appeal. Architects often use it as decorative facades. The mesh allows for light and air to pass through, enhancing the overall design.

In the food industry, stainless steel woven wire mesh is critical. Its durability and resistance to corrosion make it suitable for equipment and filtration systems. These systems ensure that food products are safe and free from contaminants. The mesh's fine openings help separate unwanted particles from liquids. However, maintenance can be challenging. Cleaning procedures must be effective to prevent buildup.

Another area of application is in the automotive industry. Stainless steel woven wire mesh serves in filters and screens. It helps improve engine efficiency and air quality. However, the mesh's performance can be affected by extreme heat. Engineers often need to reassess material choices to ensure reliability. Adjustments are crucial for optimal functionality. Overall, while stainless steel woven wire mesh offers many benefits, ongoing evaluation of its applications remains essential.

Benefits of Using Stainless Steel Woven Wire Mesh in Various Sectors

Stainless steel woven wire mesh is gaining popularity across different sectors. Its durability and resistance to corrosion make it an ideal choice in various applications. This material is often used in filtering, safety, and architectural designs. It provides strength while allowing airflow and visibility, making it versatile.

In the food and beverage industry, stainless steel mesh ensures that contaminants are kept at bay. It is easy to clean and maintain, enhancing hygiene standards. However, some users notice that it can be expensive. This raises concerns about budget constraints for smaller operations. Still, individuals should weigh the long-term benefits against initial costs.

In construction and manufacturing, this mesh serves structural purposes. It can reinforce buildings and help with noise reduction. Yet, not all designs utilize the mesh effectively. Poor design choices can lead to drawbacks. Different sectors often face unique challenges when implementing stainless steel woven wire mesh. Understanding these challenges can guide better choices in the future.

Innovative Designs and Features of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is more than just a functional material. Its innovative designs are catching attention across various industries. The intricate patterns allow for increased airflow and light penetration, making it ideal for architectural applications. Many designs offer minimalist aesthetics while ensuring strength and durability.

In the world of filtration, stainless steel mesh stands out. Its precise weave captures particles without compromising flow. This offers a reliable solution in industrial processes. However, some designs do not address all specific needs. Adjustments are often required to enhance performance. Regular reviews and updates can improve efficiency over time.

The versatility of stainless steel woven wire mesh is notable. From agriculture to food processing, it serves diverse purposes. Yet, some applications reveal limitations in mesh size choices. Customers may find it challenging to get the exact specifications they need. Continuous innovation is crucial to meet evolving demands. Engaging with users for feedback should be a priority for future designs.

Comparative Analysis: Stainless Steel Woven Wire Mesh vs. Other Materials

Stainless steel woven wire mesh is increasingly favored in various industries. Its unique properties often make it a better choice compared to other materials. For example, it is more resistant to corrosion than many alternatives like plastic or untreated metals. This makes it ideal for use in harsh environments.

When comparing it to options like aluminum or nylon mesh, stainless steel stands out. Its durability is unmatched. Aluminum may be lightweight, but it lacks the tensile strength of stainless steel. Nylon mesh can degrade over time. It can also be affected by UV exposure. Choosing the right material is crucial for long-term applications.

Tip: Always assess the environment where the mesh will be used. Will it be exposed to moisture, heat, or chemicals? These factors greatly influence the performance of the material.

Another aspect is aesthetics. Stainless steel mesh can offer a sleek and modern appearance in architectural designs. Other materials may not provide the same visual appeal. However, sometimes, stainless steel can be more challenging to handle and install. This requires skilled labor and careful planning.

Tip: Consider the installation process before deciding. If the project is complex, you may need professional help. Balance between beauty and practicality in your choice.

2026 Top Uses of Stainless Steel Woven Wire Mesh

| Application | Benefits of Stainless Steel Woven Wire Mesh | Comparison with Other Materials |

|---|---|---|

| Filtration | Corrosion resistance and durability | Better than plastic; not as effective as some ceramics |

| Construction | Strength and aesthetic appeal | Superior to wood and aluminum |

| Architectural Applications | Versatility in design and high corrosion resistance | More durable than plastic or treated wood |

| Animal Husbandry | Hygienic and easy to clean | Better longevity compared to galvanized wire |

| Food Processing | Non-reactive and easy to sanitize | Safer than plastic in high-temperature environments |

| Industrial Use | Robust and reliable performance | Outperforms fiberglass in strength and durability |

Future Trends and Developments in Stainless Steel Woven Wire Mesh Usage

The future of stainless steel woven wire mesh looks promising. Industries are increasingly recognizing its versatility and strength. Applications in architecture and construction are expanding rapidly. Designers appreciate its aesthetic appeal combined with durability. This blend of form and function opens new doors.

One notable trend is its use in protective barriers. These barriers are crucial in public spaces. They provide safety while allowing visibility. In agricultural settings, stainless steel mesh is a game changer. It protects crops while ensuring proper airflow. Farmers report higher yields and fewer pests.

**Tips:**

Consider light weight when selecting mesh. Choosing a lighter option can ease installation. Always assess the environment for corrosion risks. Stainless steel is resistant but not invincible. Regular maintenance can prolong its lifespan. Lastly, test different weaves for your specific needs. A fine weave might suit filtration, while a coarser one is better for fencing. Choosing the right specifications is key.

2026 Top Uses of Stainless Steel Woven Wire Mesh

This chart illustrates the projected top uses of stainless steel woven wire mesh in 2026, showcasing the trends and developments in various industries. The data reflects the anticipated applications that are expected to dominate the market.